HORAS Digital Relay Development Project

— Written 2023 —

HORAS is a Hybrid Overcurrent Relay Solution for Automated Substations.

This project involved the design and development of the HORAS Digital Relay, a critical solution for electrical grid protection and monitoring. The relay integrates multiple functionalities such as fault detection, data logging, and SCADA system communication, offering seamless control of power distribution networks.

MY ROLE

Early in 2017, I led one of my first projects, which aimed to develop a functioning digital relay prototype for educational purposes. The objective was to create a simplified yet fully operational model, providing hands-on learning in electrical protection systems. Through this project, I gained foundational experience in hardware-software integration and project management.

I directed a multi-disciplinary team of 15 engineers, overseeing both hardware and software development phases. My responsibilities included:

Team Collaboration: Balancing workload, resolving blockers, and facilitating brainstorming sessions to encourage cross-functional problem-solving. This experience taught me how to manage team dynamics effectively, ensuring each team member was engaged and aligned with project goals.

By maintaining open lines of communication and fostering a collaborative environment, I ensured that the team could adapt to challenges, stay on track, and deliver a high-quality prototype within the planned timeframe.

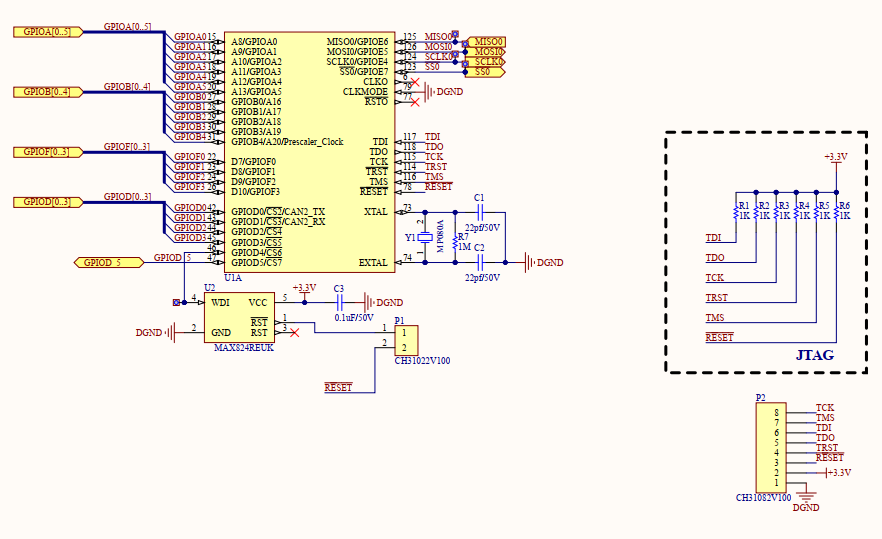

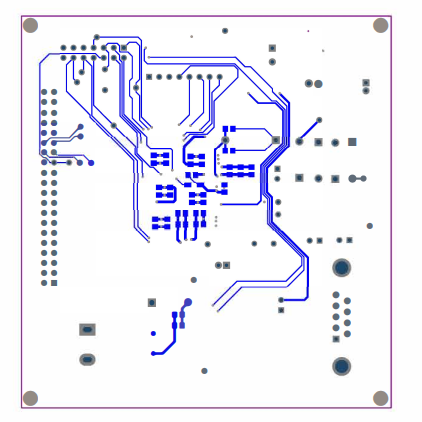

Hardware Management: Coordinated the development of three PCBs—I/O Board, Control Board, and Communication Board—aligned with the system architecture.

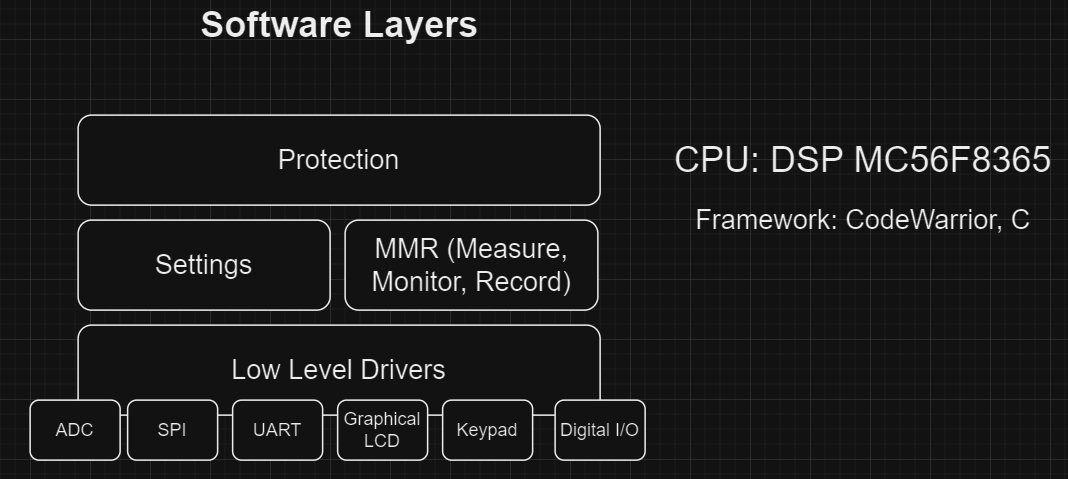

Software Integration: Managed firmware development for protection algorithms, MMI (LCD/keypad) interactions, and SCADA communication.

Vendor Communication: Collaborated with suppliers for component sourcing and ensured timely delivery.

Project Phases

Phase 1: Hardware Development (~ 5-6 months)

Designed and developed three custom PCBs (I/O, Control, and Communication boards).

Integrated signal conditioning, CPU control, and RS485/RS232 communication modules.

Modules & Integration Testing.

Phase 2: Software Development & Integration (~ 4-5 months)

Implemented real-time protection algorithms to handle overcurrent, ground fault, and voltage imbalances.

Developed firmware for event logging, inrush current management, and SCADA communication.

Managed user interaction design with LCD and keypad interfaces and tested system usability.

Project Features & Technical Highlights

Multi-function Protection: HORAS can be universally used in directional overcurrent protection applications such as feeder protection, particularly with double transmission

circuits, parallel transformers, double / multi-infeed transmission, power reversal, and possible system unbalance.SCADA Integration: HORAS has a PC user interface, which is provided, via RS232 port. In

addition, an RS485 serial communication port is provided for SCADA purposes.Man-Machine Interface (MMI): HORAS contains a front mounted with optionally Arabic supports, 8 line 16 characters, and backlight LCD display and Arabic keypad. The

sixteen-button Arabic keypad allows the user to easily interrogate the relay.Data Logging & Time Synchronization: HORAS captures the major events and automatically transfers them to the SCADA via the RS485 serial port. It also stores up to 100 events stamped with date and time to the nearest 1 millisecond. This provides the information needed to determine a sequence of events, that facilitates diagnosis of

switching panel operation. Timestamped event records via IRIG-B.

Technologies & Tools Used

CodeWarrior IDE & C Programming: Developed firmware and real-time protection algorithms using C language for optimal performance.

Altium Designer: Used for designing and simulating PCBs to meet signal conditioning and control requirements.

Excel Sheets & Trello: Managed tasks, timelines, and milestones effectively using Trello for tracking and Excel for budgeting and analysis.

Vendor Communication: Collaborated with Chinese suppliers through Alibaba for sourcing components and relied on PCBWay for custom PCB manufacturing.

P.S. Attaching sample images of project files for reference.

*This project is showcased for portfolio purposes only. All logos, trademarks, and brand names belong to their respective owners.